Products

Thioglycolic acid CAS No. 34590-94-8

Product Description

| Designation | Dipropylene glycol monomethyl ether |

| Alias | Dipropylene glycol monomethyl ether; Di(propylene glycol) methyl ether |

| CAS No. | 34590-94-8 |

| EINECS No. | 252-104-2 |

| Molecular Formula | C7H16O3 |

| Molecular weight | 148.2 |

| InChI | InChI=1/C7H16O3/c1-6(4-8)10-5-7(2)9-3/h6-8H,4-5H2,1-3H3 |

| Density | 0.951 |

| Boiling point | 190℃ |

| Flash Point | 166℉ |

| Physical and chemical properties | Properties Colorless transparent viscous liquid. Has a pleasant odor. Melting point -80℃Boiling point 187.2℃Relative density 0.9608 Refractive index 1.4220 Flash point 82℃ Solubility Miscible with water and many organic solvents. |

| Uses | Used as a solvent for nitrocellulose, ethylcellulose, polyvinyl acetate, etc. |

| Security Terminology | S23:;S24/25:; |

*The parameters are for reference only. For details, refer to COA

Properties

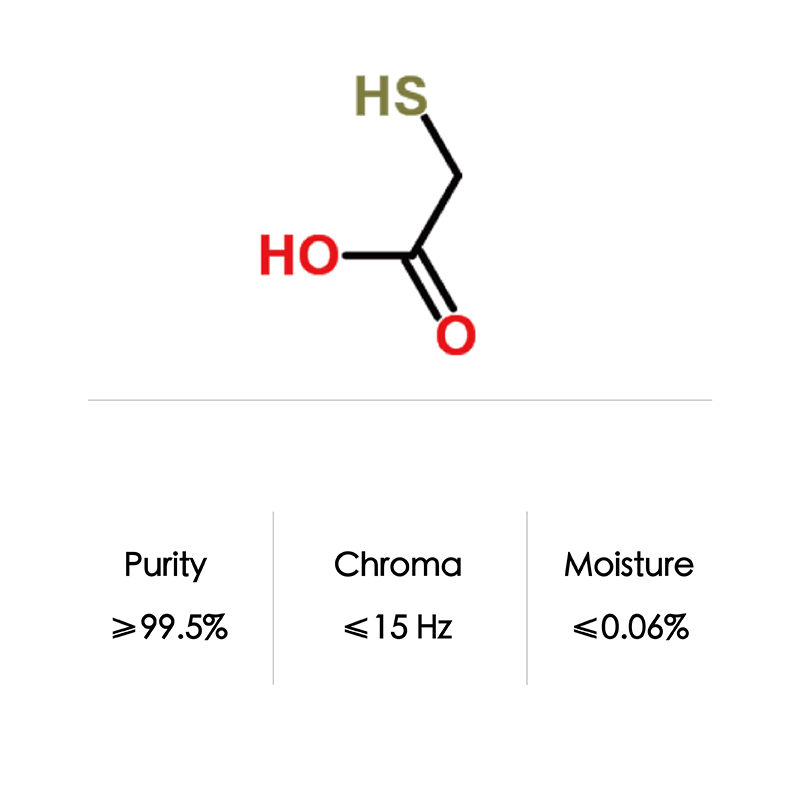

| Formula | C2H4O2S | |

| CAS NO | 68-11-1 | |

| appearance | colorless, transparent, viscous liquid | |

| density | 1.3±0.1 g/cm3 | |

| boiling point | 225.5±0.0 °C at 760 mmHg | |

| flash(ing) point | 99.8±22.6 °C | |

| packaging | drum/ISO Tank | |

| Storage | Store in a cool, ventilated, dry place, isolated from the fire source, loading and unloading transportation should be stored in accordance with the provisions of flammable toxic chemicals | |

Application

| Mainly used as curling agent, hair removal agent, polyvinyl chloride low toxicity or non-toxic stabilizer, polymerization initiator, accelerator and chain transfer agent, metal surface treatment agent. |

Dipropylene glycol methyl ether is an organic solvent with a variety of industrial and commercial uses.It finds use as a less volatile alternative to propylene glycol methyl ether and other glycol ethers. The commercial product is typically a mixture of four isomers.

Used as a solvent for nitrocellulose, ethyl cellulose, polyvinyl acetate, etc.; as a solvent for nitrocellulose, ethyl cellulose, polyvinyl acetate, etc., as a solvent for paints and dyes, and as a brake fluid component. Used as a solvent for printing ink and enamel, and also used as a solvent for washing cutting oil and working oil. Used as a coupling agent for water-based diluted paints (often mixed);

Active solvents for water-based paints;

Solvent and coupling agent for household and industrial cleaners, grease and paint removers, metal cleaners, hard surface cleaners;

Basic solvents and coupling agents for solvent-based screen printing inks;

Coupling agent and solvent for vat dye fabrics;

Coupling agent and skin care agent for cosmetic formulations; stabilizer for agricultural pesticides; coagulant for ground brighteners.

Application Areas

Coatings:Good solvency for resins including acrylics, epoxies, alkyds, nitrocellulose resins and polyurethane resins. Relatively low vapor pressure and slow evaporation rate, complete water miscibility and good compounding properties.

Cleaning agent: low surface tension, low aromatic odor and low evaporation rate. Good solubility for both polar and non-polar substances, it is a good choice for dewaxing and floor cleaning.

Advantage

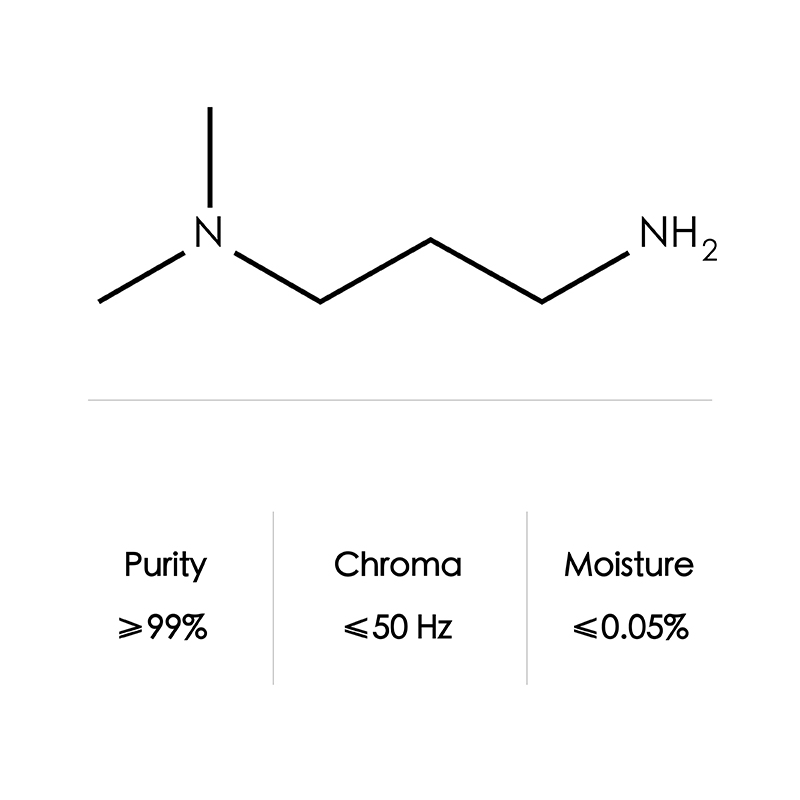

Product quality, sufficient quantity, effective delivery, high quality of service It has an advantage over a similar amine, ethanolamine, in that a higher concentration may be used for the same corrosion potential. This allows refiners to scrub hydrogen sulfide at a lower circulating amine rate with less overall energy usage.